You are here:

- CMP Home >

- Web Exhibits >

- Stereoscopic Images >

- Other Ohio

- SUBJECT:

- COMPANY:

- GEOGRAPHIC LOCATION

Stereoscopic Images of Cleveland in 3-D

Other Ohio

- This gallery contains 17 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

Method of Placing Material in Furnace — Plate Glass Works, Rossford, O.

Plate glass is made of pure sand, carbonate of lime, sulphate of sodam and carbon in the form of coke or coal. These materials must first be melted in pots or closed furnaces. The view here shows the method of filling the furnace from the conveyors. You will observe that the great dipperused has a long handle, so that men may stand away from the flames. The heat from the open furnace is intense. The dipper is attached to a small truck so that it can be pulled along from pail to pail. Thes pails are also suspended and fastened to a steel overhead truck directly above the furnace. As soon as the dipper is full it is pushed far back into the furnace and the material is dumped out by turning the dipper over.

After the sand and other materials are melted and changed into a pasty substance, this paste is poured on a cast-iron rolling table. The table is mounted on a truck which runs on rails so that it can be shifted from point to point in the factory. Here, on these great, smooth, sheet-iron tables, a heavy roller passes over the paste. This smoothes out the substance just as your mother rolls pie dough. These rollers weigh as mush as five tons. Just ahead of the big roller, and on either side of it, run two guards which keep the pasty glass from spreading out too widely.

The third process is that of annealing or colling the glass. The sheet of plate glass remains on the iron table where it has been rolled until it stiffens a bit. The, with two or three other sheets, it is lifted by a crane into a fire-brick kiln. Here, it rests on a floor of hot bricks. The kiln openings are built up, and the glass is cooled gradually for 3 or 4 days. The gradual cooling prevents cracking, and makes the glass tough. -

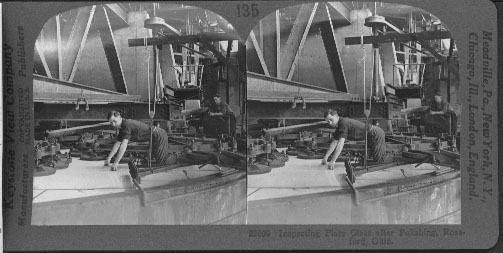

Inspecting Plate Glass after Polishing, Rossford, Ohio

After the plate glass has been rolled and properly cooled (annealed) it is taken to a cutting room where it can be shaped to a proper size.

The big plates are then moved to the polishing room. The polishing consists of three processes: grinding, smoothing and polishing. Grinding and smoothing are done almost in the same way. Rotating tables, wheels of iron such as you see are let down on the surface of the glass. Emery, fine sand, or carborundum is sprinkled on the surface. The tables of iron are let down until they fit closely against the surface of the glass and then are set in motion. The fine particles of emery, etc., cut the surface of the glass very smooth.

The next process, that of smoothing, differs from the grinding only in the fineness of the sand or emery used.

The last process is that of polishing. Revolving plates are covered with leather or some other soft material. The rubbing that the surface of the glass gets gives it a fine luster. The plates are then ready for shipping.

The United States leads every country in the world in the manufacture of glassware. The 1910 census shows that during the previous year the value of our output was $92,000,000. Our chief glass manufacturing states are New Jersey, Pennsylvania, Ohio, Indiana, and Illinois. The industry came to center in these sections because of the excellent supply of fuel. Muncie, Indiana, and other cities in that district, used their natural gas to develop their glass factories. Pennsylvania makes over one-third of the glass we produce, and the Middle Western States make another third. Belgium has the greatest plate glass factories in the world. -

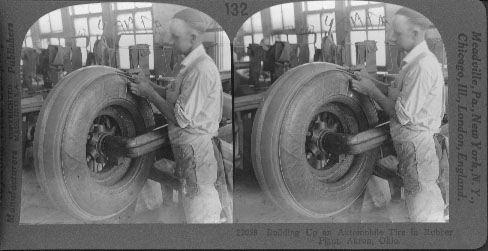

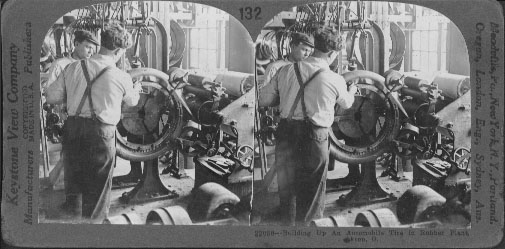

Building Up an Automobile Tire in Rubber Plant, Akron, Ohio

In the crude rubber received at the factory are sticks, dirt, bits of leaves, and beetles. These are removed by grinding the rubber in a water bath. The particles of dirt are thus washed away. The rubber is now pure enough for the first process of manufacture. The next step is to mix the rubber with chemicals. This is called compounding. In the factory here shown four or five hundred different chemicals are used to compund with rubber. Some of these are to give strength and toughness, others to give color to the rubber. It is possible to make rubber that is tougher than steel. The rubber is now ready for manufacturing purposes. What next happens to it depends on the uses to which it is to be put. For example, if it is to be made into the bandages that dentists stretch across the mouths of patients, it must be rolled very thin. This process is called sheeting. One of the greatest uses for rubber today is in the manufacture of automobile tires. You see here an automobile tire being built up. The framework of a tire is its body of fabirc or tought cloth. On an iron core, the shape of the tire, this fabric is first wound in several thicknesses. This is what the men here are doing. It is a work that demands care and skill. To become an expert workman in this department a man must have a steady hand, deft fingers, a clear eye, and good judgment. There is another way of building up tires. This is by using two crossed layers of heavy cords instead of fabric to wrap about the iron core. These cords have been filled with a rubber solution under high pressure. They are laid on the core by a machine. A tire so built up is called a Silvertown. -

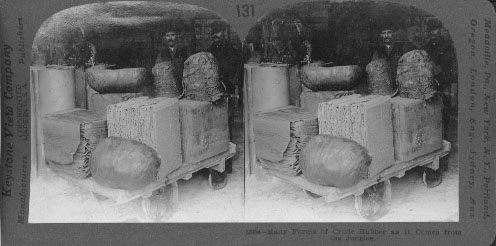

Many Forms of Crude Rubber as It Comes from the Jungle.

Forms of Crude Rubber, Akron, Ohio: This picture was taken in a great rubber goods factory in Akron, Ohio. The raw rubber you see here has come from several places in the tropics. For rubber trees grow in hot countries only, such as Brazil, Mexico, and Africa. The rubber tree is a tall, straight tree, often times 60 feet high. Its bark looks like that of the beech, and it has graceful plumes for leaves. Between the bark and the wood is a gummy fluid called latex. It is not the sap of the tree. From latex crude rubber is made. On the upper Amazon the natives go into the jungles in October to gather rubber. They tap the trees in two ways. One is by cutting the bark in a wide gash that girdles the trunk in a spiral. A trough or pail is set, and into this the latex flows from the gash. Each day the gash is extended. The other way is to tap the trees in much the same manner as sugar maples. On top of the latex so gathered a sort of cream rises. The native dips a paddle in this and holds it over a smudge of palm leaves or nuts until the latex dries. This plan he continues till he has a great ball of the size you see. The crude rubber is brought down the Amazon River in boats. Para is the chief city of the world In the export of raw rubber. In the East Indies there are many rubber plantations. There the latex is thickened by an acid, and the rubber is rolled into sheets. It is these sheets that you see on the truck. The United States imports yearly over 100,000,000 pounds of rubber. This is almost as much as Great Britain, Germany, and France combined import in the same time. Lat. 41 N.; Long. 81 W. -

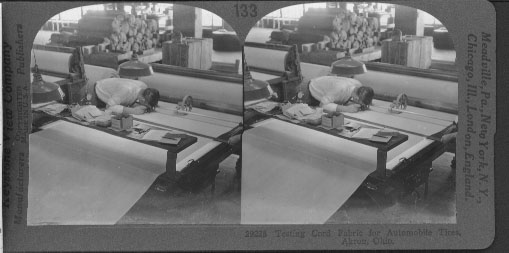

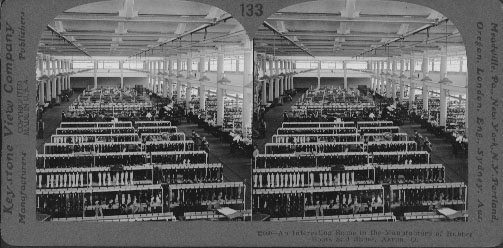

Testing Cord Fabric for Automobile Tires, Akron, Ohio

We think of automobile tires as "made of rubber." This is partly, but not wholly true. Tires are made of rubber mixed ("compounded") with other substances such as sulphur, clar, zinc oxide, carbon-black (soot from burned gas or oil), and lime, for various purposes. For rubber may be as flexible as a toy balloon or as hard as a solid tire for trucks which carry ten-ton loads.

Cotton cloth, made from long-staple cotton, is also a very important part of a tire. Heavy thread of such cotton are woven into wide sheets of cord fabric such as you see in this view. The workman in the view is inspecting the cotton fabric while it is passing over a glass table that has strong lights underneath it. He is examining the material through a magnifying glass for he must make sure it is perfect.

The cord fabric is ironed between hot rollers to make it ready for "calendering" with rubber. "Calendering" is the process that brings rubber and cotton together in one sheet. A sheet of cotton is run between heavy rollers and the rubber is pressed in between the threads of cotton so that they are like one piece of material. Many layers of such material are used in a tire.

Notice that in this view a workman is doing a very important piece of work that cannot be trusted to a machine. Machines that do wonderful things for us have been invented, but they can never take the place of a person when careful thought and judgement are needed. -

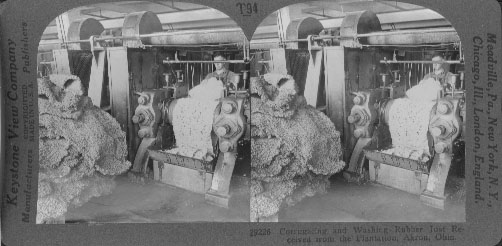

Corrugating and Washing Rubber Just Received from the Plantation, Akron, Ohio

This picture was taken in a great rubber goods factory in Akron, Ohio. The rubber is being washed by passing through great rollers over which water is flowing. Washing is the first thing done to rubber after it arrives in our factories from the tropics. The rollers also "corrugate" the rubber; that is, they press the surface into grooves and ridges. This is a sort of kneading process which breaks up particles of solid impurities in the raw rubber and thus aids materially in the washing process.

Rubber tree grow in hot countries. The tree are very tall and straight. Their bark is much like that of our beech trees. Under the bark is a gummy fluid. This fluid is called latex. From this latex, crude rubber is made. To get the latex the trees are gashed or tapped. The gummy fluid flows slowly into pails set to catch it. A pail of latex looks much like a pail of milk. Just as cream rises on milk, so rubber rises to the top of latex.

A workman builds a smoldering fire of leaves and nuts. Then he dips a paddle into the latex. Next he holds the paddle over the fire until the heat evaporates the water, leaving on his paddle a thin coating of rubber. He then dips his paddle again into the latex and again holds it over the fire. He continues doing this until his paddle has on it a thick coating of rubber. Then he cuts off the rubber and rolls it into a ball. The balls are taken to market and shipped to factories. In some countries rubber is thickened by the use of an acid.

Brazil, Ceylon, the East Indies, Africa, and Mexico all export crude rubber. Much of the rubber used in this country comes from South America. Para, Brazil, is a port noted for shipping great quantities of rubber. -

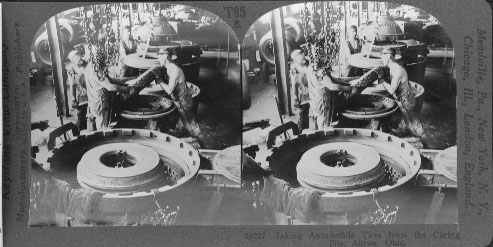

Taking Automobile Tires from the Curing Pits, Akron, Ohio

n this view the tires have just gone through the "curing" process. They are being removed from the steel forms in which they were placed for that process. "Curing" means "vulcanizing." Vulcanizing a tire means applying great heat and pressure to it. So, while in those steel forms, the tire were heated very hot and pressed very hard at the same time. The process (vulcanizing) makes the tire strong enough to stand being inflated ("blown up") by air. It also makes them strong enough to travel thousands of miles over pavements and dirt roads in all kinds of weather.

Before a method of vulcanizing rubber was discovered, our rubber goods were few and far from satisfactory. A rubber rain coat in winter became so stiff that it would stand alone. In summer the same coat became soft and stickey and stretched out of shape. Charles Goodyear, and American living in Connecticut, spent nine years in hard work and poverty trying to find a way to treat rubber so that it would not crack in winter or melt in summer. One day he threw a lump of rubber mixed with sulphur into the fire. Great was his surprise and joy to find that the fire did what he had been trying to do; it toughened the mass. Over five more years he worked to perfect his process. Without Mr. Goodyear's wonderful discovery many articles now made of vulcanized rubber would be unknown. Certainly automobile tires such as we see today would be impossible. The process of hardening rubber was called "vulcanizing" in honor of Vulcan, the Roman god of fire. -

Building Up an Automobile Tire in Rubber Plant, Akron, Ohio 2

The material that has been used to make up this automobile tire has passed through many machines and has been worked on by many other skilled workmen before it has reached this workman. This man is carefully trimming one of the many layers that make up this large tire. Before this tire is finished, it must be placed in a steel mould of just the right size and tread design. This mould has a metal center part which will keep the inside of the tire hollow and in shape. While in that mould the tire will be heated very hot and at the same time be subjected to great pressure. After that process the tire will go to the inspection room. There it will be thoroughly examined. Those tire that are found to be perfect will be shipped away to be sold. If any are not quite prefect, they will be marked "seconds" and sold at a lower price than the perfect ones.

You may see this very tire pass you on the road, for it is being made for one of the large, swift buses that carry passengers from one city to another.

To realize the importance of tire manufacturing you have only to remember that all automobiles must be equipped with tires, and then think of the many purposes for which automobiles are used. Perhaps you will think first of the many automobiles used for pleasure. Next remember that there is hardly a great business in the world that does not make use of automobiles. All cars used for these, and many other purposes, must have tires; therefore, tire manufacturing has become a great industry of our country. -

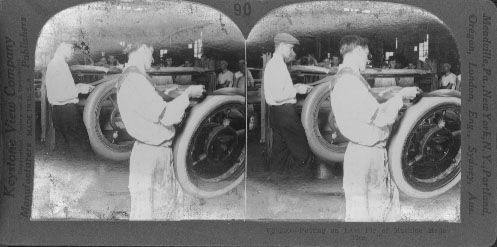

Putting on Last Ply of Machine Made Tire

In the crude rubber received at the factory are sticks, dirt, bits or leaves, and the beetles. These are removed by grinding the rubber in a water bath. The particles of dirt are thus washed away. The rubber is now pure enough for the first process of manufacture.

The next step is to mix the rubber with chemicals. This is called compounding. In the factory her shown four or five hundred different chemicals are used to compound with rubber. Some of these are to give strength and toughness, others to give color to the rubber. It is possible to make rubber that is tougher than steel. The rubber is now ready for manufacturing purposes. What next happens to it depends on the uses to which it is to be put. For example, if it is to be made into bandages that dentists stretch across the mouths of patients, it must be rolled very thin. This process is called sheeting.

One of the greatest uses for rubber today is in the manufacture of automobile tires. You see here an automobile tire being built up. The framework of a tire is its body of fabric or tough cloth. On an iron core, the shape of the tire, this fabric is first wound in several thicknesses. It is a work that demands care and skill. To become an expert workman in this department a man must have a steady hand, deft fingers, a clear eye, and good judgment.

There is another way of building up tires. This is by using two crossed layers of heavy cords instead of fabric to wrap about the iron core. These cords have been filled with a rubber solution under high pressure. They are laid on the core by a machine. A tire so built up is called a Cord. Many tire are thus built at Akron, Ohio. -

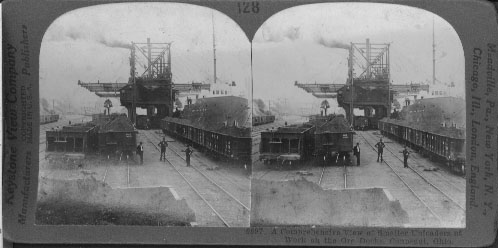

A Comprehensive View of Smaller Unloaders at Work on the Ore Docks, Conneaut, Ohio.

VIEW OF ORE UNLOADERS AT WORK, CONNEAUT, OHIO: On the right is a lake steamer laden with ore from the Lake Superior district. It is at the docks alongside an unloader. This unloader is only a huge steel framework with a number of tracks extending on one side over the dock, and on the other side over the switches. The trucks on these overhead tracks are equipped with buckets which dip the ore out of the hold of the vessel. The bucket is pulled by an engine, up to the truck to which it hooks. This releases the truck, which travels to the other end of its tracks, and there the bucket is lowered and emptied.

The view shows one car on the right being loaded. The truck on the left is dumping its bucket of ore into the freight car. Four series of cars can be loaded here at the same time. The hoist, or steel framework, is 60 feet high and 180 feet long. The bucket is of the type called calm shell. The steel cars into which the ore is dumped are shaped inside like hoppers. That is, their bottoms are sloped. When these cars reach the steel mills, the hopper is opened at the bottom and the ore is dropped into bins below the tracks. Each car can carry 50 tons of ore, and on the return journey will carry 38 tons of coal.

You will observe lying on blocks of wood on the ground, two pairs of steel cables. Each of these cables is slowly moving. When it is necessary to move the car, or the series of cars, to shift them under the buckets, a chain is attached from the cable to the car. When the car had been brought into the proper position the chain is unhooked. -

Making Rubber Boots and Shoes, Akron, OhioIn rainy weather nothing is so much needed as a raincoat and a pair of rubber boots or overshoes. In the rubber factory you see here many kinds of rubber goods are made. Raincoats are made by the thousands. Instead of cutting each coat separately, 40 or 50 pieces of fabric are cut at one time by machinery. Each coat is so cut follows the pattern to a nicety.

Then there is the boot and shoe department. This firm makes about 25,000 pairs of boots and 25,000 pairs of "rubbers" every working day. This means that here 25,000 people could be fitted out dry shod every single day. The section shown here is the boot and "rubber" department.

Boots and "rubbers" are builty up on a boot or shoe form or last. Pieces of fabric and rubber cut to the proper shape, are laid on the form. The boot or "rubber" is then vulcanized. That is, it is heated, and the rubber particles are welded together by compressed air. This makes the boot tougher than it could possibly if built up and merely dried out in ovens.

Men working here out to be able to keep healthy on account of the good lighting and ventilation. This is a good illustration of our large modern factories. This concern employers in its various departments between 18,000 and 20,000 people. Such factories make a city famous for their product. -

Docks, switchyards and 1-ton buckets for lifting iron ore from ships to cars, Cleveland, Ohio.

We are looking north, i.e., towards Lake Erie, over the great ore docks along the "Old River Bed" canal. Here immense quantities of iron from the Lake Superior mines are transferred to trains and shipped to the famous blast furnaces and steel-mills at Youngstown, Pittsburgh and elsewhere in the Ohio river valley, 100 to 150 miles away at the southeast. The partially crushed ore in the cars here at our feet and that soft, earth-like ore in the cars beyond have both come up from near the head of Lake Superior where the biggest and richest iron mines in the whole world are being worked. The hoisting apparatus overhead makes quick work of unloading a freighter, for those suspended buckets hold a ton apiece. They are run out over a vessel, let down into the hold, filled, drawn up, slid across the intervening space and then lowered for dumping into a car, all in a space of time hardly more than it takes to tell about it. If the supply of empty cars is insufficient, the accumulating surplus forms great stock-piles like those straight ahead, at our right. Still more rapid work can be done with immense "clams" that clutch five or ten tons at once; the gigantic steel derricks of such an unloading plant loom up in the distance at our left. We can watch at short rang the operation of such powerful machines by using Stereographs 7963 or 7970. For the mining of this ore, use 7947 and 7954. For its later manufacture into steel, use 5520-5523. From Notes of Travel No. 37, copyright by Underwood & Underwood ("Docks at Cleveland, O., with apparatus for unloading iron ore" is written in six languages, including English, French, German and Russian.) -

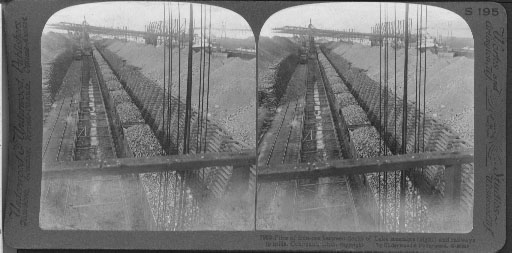

Piles of iron ore between docks of Lake steamers (right) and railways to mills, Conneaut, Ohio.

We are looking north toward Lake Erie. The steamers over there at our right are on Conneaut Creek. Over 4,000,000 tones of iron ore are brought down here every year by Lake Freighters from the richest iron mines on earth, up at the west end of Lake Superior. here are some of the last 4,000,000 now, forming the long line of stock-piles before us on either hand. Those gigantic arms that reach out over the railway track from their anchorage alongside the creek are part of the huge unloading machinery by whose means the ore in all these piles was taken out of the ships' holds and dumped here. Those long steel girders can reach away across the tracks to stock-piles on the west side. The long string of ore-laden cars is on its way to one of the big blast furnaces to b reduced to pig-iron; most of it will go through the huge converters at Youngstown or Pittsburgh and become transformed into steel— perhaps for a railway track in Africa, a bridge across a Himalayan gorge or a new office building in San Francisco. In order to see the underground mining of iron ore, use Stereograph 7954. For gigantic ore docks at the head of Lake Superior, use 7957. For the process of unloading a steamer in 10-ton handfuls, use 7970. The melting of such ore in a blast furnace can be seen with 5520. No 5523 shows the shaping of steel beams in a rolling mill. From Notes of Travel No. 37, copyright by Underwood & Underwood ("Piles of iron ore between docks and railway, Conneaut, O." is written in six languages, including English, French, German and Russian.) -

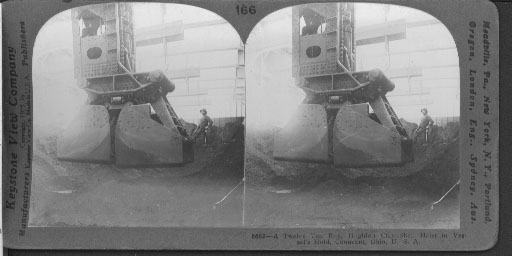

A Twelve Ton Bite, Hughlette [sic] Clam-Shell Hoist…, Conneaut.

Twelve-Ton Bite: The huge bucket has descended from its position in view 6681 through the hatchway into the hold of the vessel. The operator moved a lever, the piston-rod seen in 6681 ascended into its jacket, the great jaws closed upon 12 tons of ore and the length of the bucket from right to left was reduced from 22 feet to 9 feet. The machine to which the bucket is attached is now in the position of the second machine shown in view 6680. In less than thirty seconds the operator, by moving his levers, will cause the load to rise above the deck, the machine to back into the position of the first one seen in view 6680, and the load to drop into the transfer car. This great machine delivers its huge loads to the stock piles at the rate of one load per minute. The average load is 10 tons.

This is the hold of a modern ore boat capable of carrying 12,000 tons of ore. Only four such boats have yet been built. They are 650 feet long and 52 feet wide. The hatchways are twelve feet apart. The deck is supported by steel arches from the side of the boat. This makes the hold of the vessel one great room unobstructed by partitions or pillars of and kind. This room is 400 feet long, 50 feet wide, and 32 feet high. The numerous hatchways enable the unloaders to do the work with little or no hand labor in the hold. The Hulett bucket may be turned by its operator in and direction and moved back and forth along the hatchway at his will. -

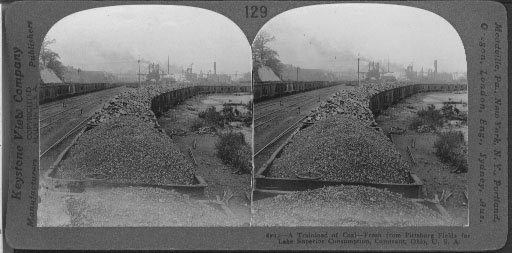

A Trainload of Coal from Pittsburgh Fields for Lake Superior Consumption, Conneaut, Ohio

There is nothing unusual about this scene. On almost any of the great railways in the eastern and middle western sections of our country such trainloads of coal as this can be seen any day. But there is a particular interest connected with this and similar trainloads of coal running from the Pittsburgh district to the Great Lakes. Our greatest iron ore deposit lies at the western end of Lake Superior. In this district, however, there are no coal fields. One of the two things must be done. Either coal must be taken to the ore fields, or the iron must be brought to the coal fields. Coal is needed to heat the iron so that it can be made into steel. When the Lake Superior iron district was first worked, all the ore was carried by huge lake boats to the coal district. But by this method, theses boats had to return empty. This was a great waste. Now the shipping is carried forward both ways. Iron and steel refineries have been built in the Superior District. The vessels that bring iron ore east, carry back heavy cargos of coal to be used in the Superior iron district. This trainload of coal that you see will be put on board one of these ships and unloaded at Duluth or Superior, not far distant from the iron ore area. This make the ports along the southern shore of Lake Erie the natural exchange place of coal and iron. Among these important ports are Buffalo, Erie, Cleveland, Toledo, Ashtabula, Lorain, and Conneaut, the city here shown. Locate each of these cities on your map. Trace a shipment of coal from Conneaut to Duluth. Through what waters does it pass? Lat. 42 N.; Long. 81 W. -

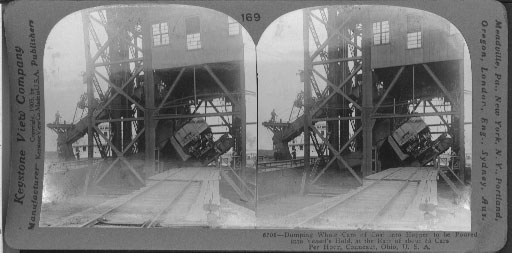

Dumping Whole Cars of Coal into a Hopper to be Poured into Vessel's Hold, Conneaut, Ohio.

This picture shows you how coal is quickly and easily transferred from the railroad cars to the ship's hold. The car which you see on the dock is held by great clamps to the platform. Then the platform, with the car fastened to it, is raised and tipped so that all the coal pours out into a hopper. Other machinery then moves the coal from the hopper to the ship's hold.

The dock in the view is at Conneaut, Ohio. Conneaut is one of the ports along the southern shore of Lake Erie, which has become and exchange place for coal and iron. Our greatest iron ore deposit lies at the western end of Lake Superior. In that district, however, there are no coal fields, and coal must be had to heat the iron ore, and to furnish carbon to mix with it, so that the iron can be made into steel. One of two things must be done. Either the coal must be taken to the iron fields, or the iron must be brought to the coal fields. At first, the iron was taken to the coal fields, and empty boats returned for more ore. Now steel refineries have been built in the Superior district similar to those near the coal fields in the east, so that today the shipping is carried on both ways. The vessels that carry iron east, carry back coal to be used in the Superior district. The coal being loaded at Conneaut will be taken to Duluth or Superior not far from the iron ore area.

Buffalo, Cleveland, Toledo, Ashtabula and Lorain are other ports which have become exchange places for coal and iron. Locate these posts. -

A Great Lakes Freighter Coming Into Harbor, Conneaut, Ohio, U.S.A.

The smaller ore boats carry about 3,000 tons of ore while the largest carry more than 12,000 tons. Ths one shown in this view is a medium-sized boat and may be carrying 5,000 tons. The view is to the north across Lake Erie. On the west side of the harbor are two lighthouses. These are range lights. They are placed on the west side of all Lake Erie harbors. At night, the boat must get in line or in range with these two lights while yet several miles from shore. Then by keeping in range with then it is sure to make the harbor.

The report of the collector of the U.S. Customs shows that 1362 vessels entered Conneaut Harbor during 1940. The receipts were 4,038,755 tons of iron ore; 52,104 tons of pier stone; and 458 tons of other freight. This was more iron ore than received at any other port on the Great Lakes. The iron ore receipts for 1950 will probably be 5,250,000 tons, but Ashtabula, Ohio will receive somewhat more than Conneaut this season. The shipments from Conneaut Harbor for 1940 amounted to but 413,320 tons, 98 per cent of which was coal, and one-third of this coal was used as fuel on the boats.

The receipts and shipments mentioned concerned domestic commerce only. The imports for 1940 were valued at $53,216. They were mainly lumber. The exports were valued at $3,774,562, of which about 15 percent was bituminous coal and nearly 85 percent steel rails and other forms of manufactured steel. The foreign commerce was wholly with Canada.